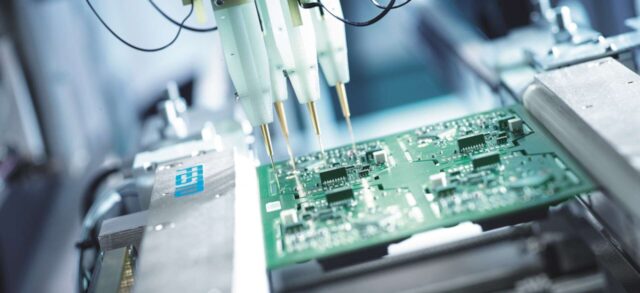

Printed circuit boards are small electronic boards that interconnect all the components of an electronic device. Their production can be both computer and machine. However, due to the needs of the market – the machine production of PCBs is the most common. Although the rule is that they are not particularly expensive, the production of PCBs, especially for certain components, still costs money. So here are some ways to reduce costs in the production and assembly of PCBs.

Production And Assembly Costs: Can We Reduce Them And How?

Most industries strive to make the best product at the most competitive price. Therefore, the same is the case with PCB manufacturers. We must emphasize that it is not always easy to make a quality product, which, in addition to all that, must be assembled – and always to accomplish the lowest price. Given the widespread use of PCBs in electronics, it is clear that we distinguish them for their purpose – but also by the sizes and materials used in manufacture. That is exactly what makes manufacturers sometimes surprised by the cost of producing and assembling PCBs. So can these costs be reduced, and in what way?

1. Make an Effective List of Materials

If you are a manufacturer of PCBs, you should apply the same rule as other manufacturers. Namely, no matter what you produce – you need to rely on following and monitoring your resources and your budget. That is why you need an efficient list, that is, the billing of materials. This list will help you better track your inventory – and better plan the procurement of components you need. Although it sounds simple, and it generally IS simple – you probably don’t even know how much BoM can help, especially with large, massive orders. Thus, you will avoid making mistakes, and having delays – but you will increase production efficiency, and save money.

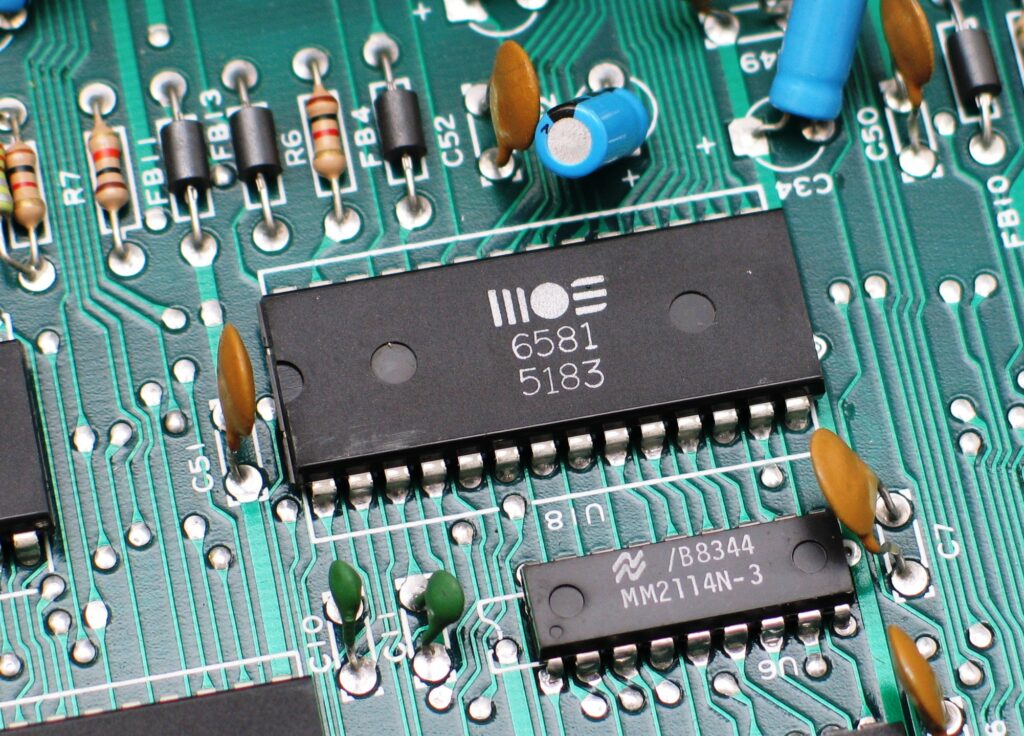

2. Perform a Detailed Analysis of the Board Before Installing the Components

Design errors and additional manual alterations – are the most often and most costly issues for PCB manufacturers. Therefore, one of the suggestions on how to reduce costs like these – is to analyze the panels before installing additional components. Of course, you can always seek Turkey PCB assembly options, but if you wish to do that yourself, then make the analysis of the board before installing components. Experts in this field always advise you to try to avoid placing small elements next to larger ones. Namely, these components can sometimes require additional soldering that is done manually – and this greatly increases the cost of production and assembly of PCBs.

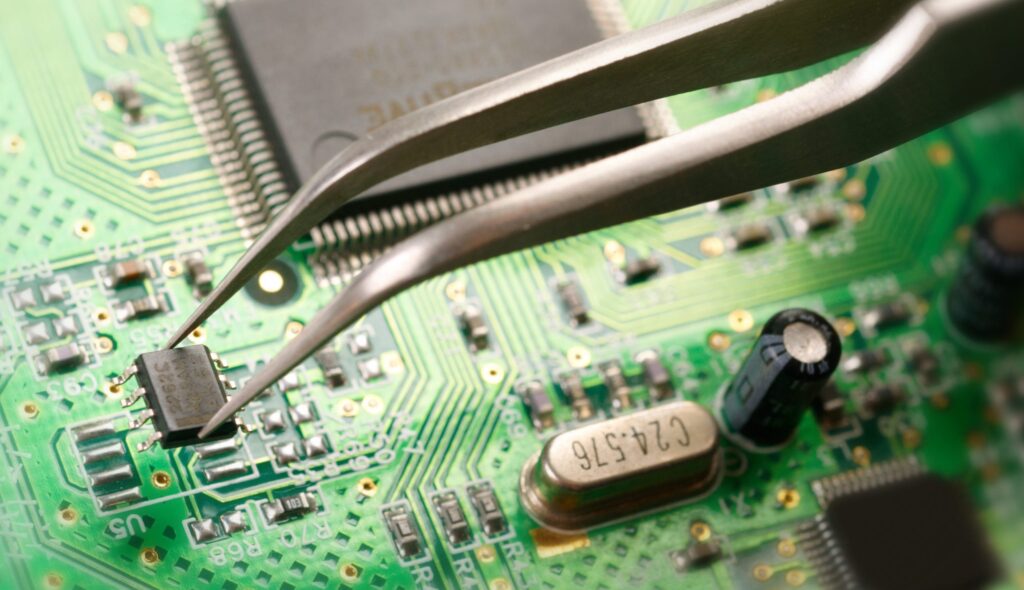

3. Make Sure Your Board Is Not Too Complex

This is certainly the best way to reduce costs in making PCBs. Namely, the simpler the design of the board is, the simpler will be the arrangement of components on it. Therefore, you’ll have less need for alterations, soldering, and the like. More complex board shapes, especially if they are irregularly shaped – will only further increase costs. Although many manufacturers stick to the original look and shape of their PCBs – in reality, it has no significance because the special shape does not add any special features to the PCB.

The Bottom Line

These are just 3 basic tips on how you can try to reduce the cost of manufacturing and assembling your PCBs. There are also other ways we could point you out – but perhaps, the best solution for any manufacturer is to control their costs in consultation with their suppliers. In the agreement you reach with them – lies the best way to save precious time and money.